打膠機的各種故障及處理方法

1、膠嘴堵塞

1. Blocked rubber nozzle

現象:膠嘴出量偏少活沒有膠點出來。

Phenomenon: the output of glue nozzle is too small, and there is no glue point.

產生原因:針孔內未完全清洗干凈,貼片膠中混入雜質,有堵孔現象,不相容的膠水相混合。

Cause: the pinhole is not completely cleaned, impurities are mixed in the patch adhesive, the hole is blocked, and incompatible glue is mixed.

解決辦法:換清潔的針頭,換質量較好的貼片膠,貼片膠牌號不應搞錯。

Solution: replace the clean needle with a good quality patch adhesive. The brand of patch adhesive should not be mistaken.

2、拉絲/拖尾

2. Wire drawing / tailing

現象:拉絲/拖尾,點膠中常見缺陷

Phenomenon: common defects in drawing / tailing and dispensing

產生原因:膠嘴內徑太小,點膠壓力太高,膠嘴離PCB的間距太大,粘膠劑過期或品質不好,貼片膠黏度太高,從冰箱中取出后未能恢復到室溫,點膠量太多等。

Causes: the inner diameter of the glue nozzle is too small, the dispensing pressure is too high, the distance between the glue nozzle and PCB is too large, the adhesive is expired or of poor quality, the stickiness of the patch is too high, it fails to return to room temperature after being taken out of the refrigerator, and the dispensing amount is too large.

解決辦法:改換內徑較大的膠嘴,降低點膠壓力,調節“止動”高度,換膠,選擇適合黏度的膠種,從冰箱中取出后應恢復到室溫(約4h),調整點膠量。

Solution: change the glue nozzle with larger inner diameter, reduce the dispensing pressure, adjust the "stop" height, change the glue, select the glue type suitable for viscosity, recover to room temperature (about 4h) after taking it out of the refrigerator, and adjust the dispensing amount.

3、固化后,元器件黏結強度不夠,波峰焊后會掉片

3. After curing, the bonding strength of components is not enough, and the chips will fall off after wave soldering

現象:固化后,元器件黏結強度不夠,低于規范值,有時用手觸摸會出現掉片。

Phenomenon: after curing, the bonding strength of components and parts is not enough, which is lower than the specification value. Sometimes the pieces will fall off when touched by hand.

產生原因:固化后工藝參數不到位,特別是溫度不夠,元件尺寸過大,吸熱量大,光固化燈老化,膠水不夠,元件/pcb有污染。

Cause: after curing, the process parameters are not in place, especially the temperature is not enough, the component size is too large, the heat absorption is large, the UV curing lamp is aging, the glue is not enough, and the component /pcb is polluted.

解決辦法:調整固化曲線,特別是提高固化溫度,通常熱固化膠的峰值固化溫度很關鍵,達到峰值溫度易引起掉片,對光固化膠來說,應觀察光固化燈是否老化,燈管是否有發黑現象,膠水的數量,元件/pcb是否有污染。

Solution: adjust the curing curve, especially increase the curing temperature. Generally, the peak curing temperature of the thermal curing adhesive is very important. Reaching the peak temperature is easy to cause chip falling. For the UV curing adhesive, observe whether the UV curing lamp is aging, whether the lamp tube is blackened, the amount of glue, and whether the components /pcb are polluted.

4、孔打

4. Punch

現象:只有點膠動作,無出現膠量。

Phenomenon: only dispensing action, no glue amount.

產生原因:混入氣泡,膠嘴堵塞。

Cause: bubbles are mixed and the rubber nozzle is blocked.

解決方法:注射筒中的膠應進行脫氣泡處理(特別是自己裝的膠),按膠嘴堵塞方法處理。

Solution: the glue in the injection cylinder should be deaerated (especially the self-contained glue) and treated according to the method of blocking the glue nozzle.

5、固化后元件引腳上浮/移位

5. Floating / shifting of component pins after curing

現象:固化后元件引腳浮起來或移位,波峰焊后錫料會進入焊盤,嚴重時會出現短路和開路。

Phenomenon: after curing, the component pins float or shift, and the tin material will enter the pad after wave soldering. In serious cases, short circuit and open circuit will occur.

產生原因:貼片膠不均勻,貼片膠量過多,貼片時元件偏移。

Cause: uneven patch glue, too much patch glue, and component offset during patch.

解決辦法:調整點膠工藝參數,控制點膠量,調整貼片工藝參數。

Solution: adjust the dispensing process parameters, control the dispensing amount, and adjust the patch process parameters.

6、元器件偏移

6. Component offset

現象:固化元器件移位,嚴重時元器件引腳不在焊盤上。

Phenomenon: the solidified components are displaced, and the component pins are not on the bonding pad in serious cases.

產生原因:貼片膠出膠量不均勻(例如片式元件兩點膠水一個多一個少),貼片時,元件移位,貼片膠黏力下降,點膠后PCB放置時間太長,膠水半固化。

Cause: the glue output of the chip adhesive is uneven (for example, the glue at two points of the chip component is more than one, and less than the other). When the chip is pasted, the component shifts, the adhesive force of the chip decreases, the PCB is placed for too long after dispensing, and the glue is semi cured.

解決辦法:

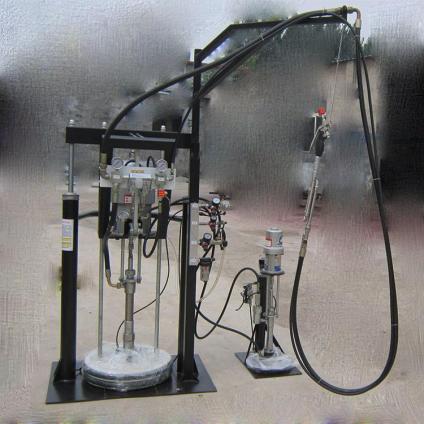

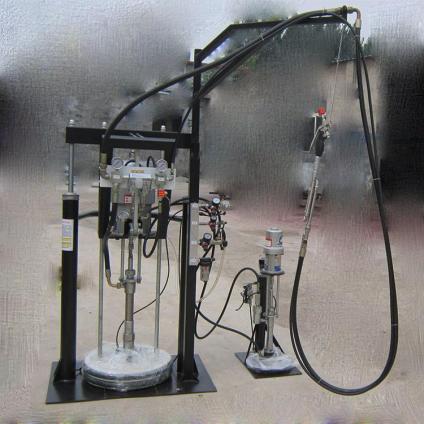

濟南雙組份打膠機廠家建議您檢查膠嘴是否有堵塞,排除出膠不均勻現象,調整貼片機工作狀態,換膠水,點膠后PCB放置時間不應過長(小于4h)。

Solution: the manufacturer of Jinan two-component glue applicator suggests that you check whether the glue nozzle is blocked, eliminate the uneven glue discharge, adjust the working state of the mounter, change the glue, and the PCB should not be placed too long (less than 4h) after dispensing.

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.vrqf.com.cn And consult our staff, will serve you wholeheartedly.

上一篇:雙組份打膠機不維護容易出現的三大問題

下一篇:怎么區分汽車車燈大燈是熱膠還是冷膠?